What Materials Are Used For Building Ships?

The economic aspect of running a merchant vessel is of prime importance as a shipowner requires a build which maximises the returns for his initial investment and covers his running costs.

This implies that the final design takes into account the economic conditions at the time of building, and also those that are likely to develop within the life of the ship.

Apart from this, the safety of seafarers on board, the type of vessel, the operational logistics of the voyages is taken into serious consideration while planning and executing the shipbuilding operations.

Most commonly used materials for shipbuilding :

Steel:

This is a highly versatile ship construction material and is used extensively on ships for the making of its integral structure and parts.

Steel has been in use for over 150 years in the shipbuilding industry, thanks to its excellent mechanical properties and low cost.

High Tensile Steels Steels which have higher strength than that of mild steel are employed in the more stressed regions of large tankers, container ships and bulk carriers. They are often used for the deck and bottom regions of larger tankers as well. As this leads to a reduction in the scantlings of these structural items, it proves advantageous both for the shipbuilder and owner.

Some integral parts of the ship that are made of steel include; the thickness stringer plate, rounded gunwales, sheerstrake, Bilge strake, deck strake in the way of the longitudinal bulkheads, main deck plating, bottom plating, keel, and the upper strake of longitudinal bulkheads. Mast tables, crosstrees, etc., may be fabricated from welded steel plates and sections. Derrick booms, as a rule, are welded lengths of seamless tubular steel.

Related Read: Shipbuilding Process – Plate Stocking, Surface Treatment and Cutting

Aluminum Alloys:

There are three main advantages which Aluminum alloys have over mild steel in the construction of ships.

1. Aluminum is lighter than mild steel and studies suggest that up to 60 percent of the weight of a steel structure can be saved by using Al alloys. For merchant vessels, this is a key advantage for increasing the cargo carrying capacity of ships.

2. Aluminum is highly resistant to corrosion

3. Its non-magnetic properties and low-cost maintenance

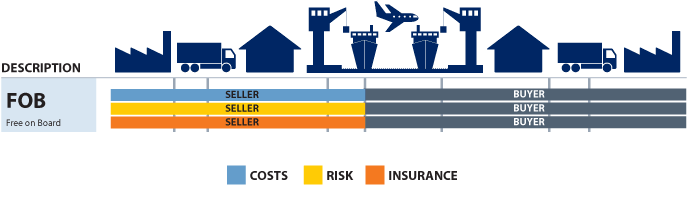

Importing Made Easy

Lonestar Global manage the end to end supply of your metal requirements. Our global shipping and logistics network provide door to door delivery for all type, weight & quantities. We manage and advise with FOB, CIF, import tax and duty at an international level.

At Lonestar Global base metal is the heart of our business and

our clients are the heartbeat

Sourcing Base Metals

Global Mill Network

World Wide Shipping

Shipping to 197 Countries

Delivered to End User

Complex Logistics Made Easy