There are many considerations to make when creating parts for aerospace applications, such as the shape, weight, and durability of a part. These factors can all affect the aircraft’s flight worthiness. For example, If a plane is too heavy, it will need extra thrust to achieve liftoff and maintain altitude—increasing fuel consumption. If the superstructure of a plane is too weak, on the other hand, it could fail mid-flight and put the occupants’ lives at risk.

For years, the go-to material for aerospace applications was aluminum. However, in recent years, aerospace manufacturers have started investigating alternatives to aluminum, one of them being aerospace grade stainless steel.

Aluminum has long been status quo material for making aircraft components because of its combination of high tensile strength, relatively light weight per cubic centimeter (approximately 2.7 g/cm3), and easy machinability in addition to strong corrosion resistance. Pure aluminum also has a relatively low cost compared to many alloys (though this varies), due to it being an atomic element.

The ultimate tensile strength (UTS) of aluminum can vary based on what the material is alloyed with. However, aluminum 6061-T6—which is over 95% pure aluminum—has a UTS of 310 MPa (45,000 psi) according to ASM. Aluminum is often noted for having a high strength compared to plain steel at low temperatures.

When making a comparison to aerospace stainless steel, it’s important to specify the exact steel alloy. This is because there are many different formulations of stainless steel—each one with its own unique characteristics.

For example, grade 304 stainless steel has a higher ultimate tensile strength than aluminum—505 MPa (73,200 psi)—but weighs 8 g/cm3, nearly triple the weight of aluminum. Additionally, 304 stainless steel for aerospace applications is highly resistant to corrosion thanks to its protective oxide layer, which inhibits oxidation.

In short, while stainless steel alloys are heavier than aluminum, they also have a higher tensile strength, shear modulus, and melting point than aluminum does.

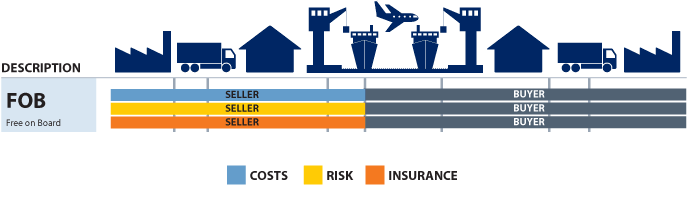

Importing Made Easy

Lonestar Global manage the end to end supply of your metal requirements. Our global shipping and logistics network provide door to door delivery for all type, weight & quantities. We manage and advise with FOB, CIF, import tax and duty at an international level.

At Lonestar Global base metal is the heart of our business and

our clients are the heartbeat

Sourcing Base Metals

Global Mill Network

World Wide Shipping

Shipping to 197 Countries

Delivered to End User

Complex Logistics Made Easy